Author's note: this might be old news to some of you. Feel free to skip if you are a seasoned string alignment pro!

I've been modifying cars for over 20 years now (it will always pain me to say that). Thus, I've probably known about string alignments for at least 18 years. It was not until recently that I started doing them myself. Why did I choose to do so, and what are the benefits and downsides? Let's take a look.

What is a string alignment?

Alignments are usually done on a lift and with the aid of a fancy machine that shoots laser beams at reflectors mounted to your wheels in order to determine the angles of the suspension. Your average professional alignment is probably around $60-80 and takes 45-90 minutes.

A string alignment uses decidedly lower-tech means to achieve the same outcome. Two strings are strung on either side of the car, and carefully centered to the chassis centerline in order to give you a point of reference in which you can measure the toe angles of each wheel individually (as opposed to toe plates, which only give you total toe for that axle). Camber and caster can be found/calculated using a digital angle finder. Steer ahead and thrust angle are typically calculated on a professional alignment, but those items are less of a concern for a race car than they are on a daily driver.

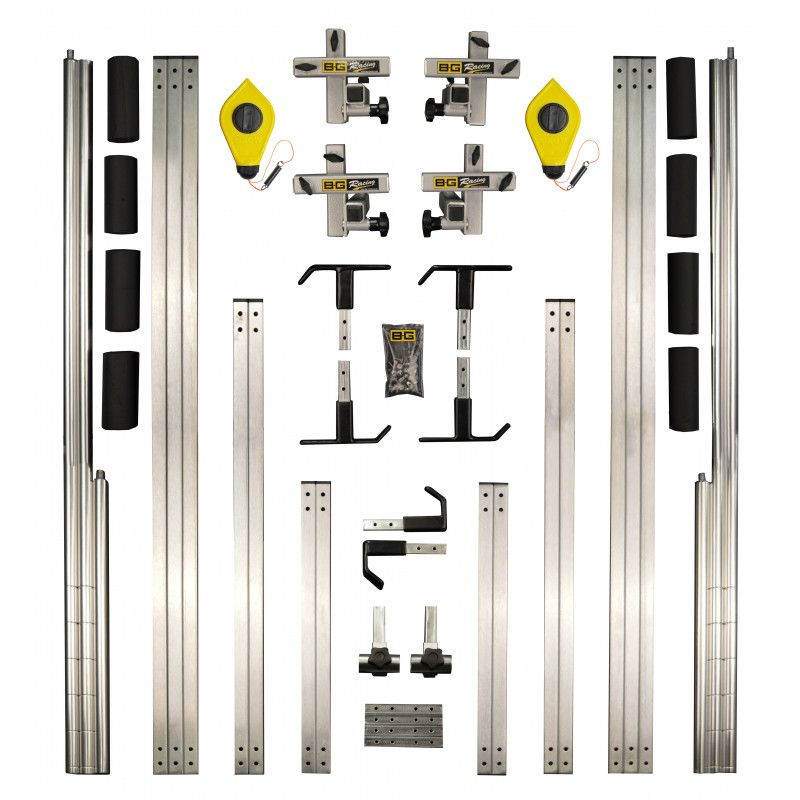

Making your own string alignment kit could be accomplished as inexpensively as $20-40, or you can buy a complete string kit are a few hundred dollars. Besides the string setup, you don't need much else to complete your alignment: a level surface, a precise ruler, a straight edge, and a digital angle finder are just about it.

The path to string.

When I first heard of string alignments, they seemed like a cheapskate thing to me. Like, why not take it to a shop that will charge you $45 (this was ~2005...), and in an hour, you could be on your merry way?

When I started getting into complicated wheel fitments (cough stance cough) I learned the value of higher end shops that will align to your specs & needs. Those alignments started costing $100-125.

Then when I started getting into track driving, I really started to understand why you'd want someone knowledgeable, experienced, and detail-oriented doing your alignments. Those alignment bills, at times, pushed over $200.

From there, I learned why you'd want to alter your alignment specs to affect the handling characteristics of the car. No longer did I look at alignments as a means to make my tires last 30,000 miles (it is more like 300 miles these days).

String isn't for everyone.

Thankfully, in my early days of track driving, I had a great alignment shop (Ernie Bello Motorsports in West Palm Beach, FL). They were right around the corner from me, they were super thorough and knowledgeable, and they were nice people! While my track car was still registered and insured, it was a no-brainer to swing around the corner and have them do my alignments.

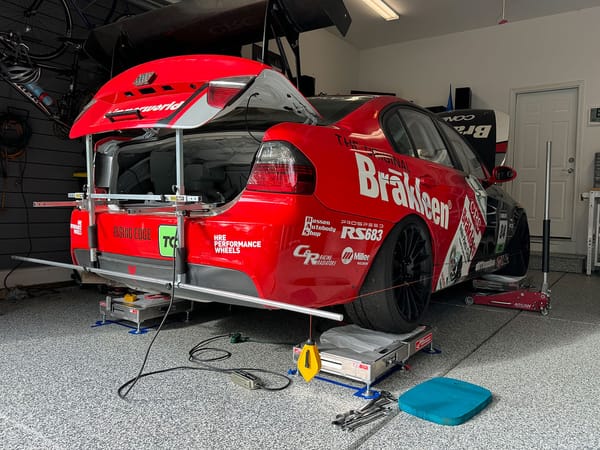

Fast forward to my move to Charlotte, NC. I no longer register any of my track cars for street use, and the only shops I'd trust to do the alignment are about 45-60 minutes away from home. Loading the trailer, traveling there, waiting on the alignment, traveling back, and unloading the trailer becomes an all-day affair.

I can't say for myself that there is any financial motivation for doing my own alignments, because I've invested a ton of money in my string setup (more on that to come later). It will take years to "pay itself off."

For me, with my track-only cars, it was about convenience and control. I don't have to spend a day getting a race car to and from from a race shop, and I don't have to go back and forth with a tech about the ins and outs of the chassis and how I want it setup.

Plus, as my friend Nick observed while helping me measure caster and leveling my corner scale pads: I just like nerdy, detailed, intricate work more than I like getting down and dirty on repair work.

Hanging by a string.

There are of course some downsides to do-it-yourself work, of any kind.

I'll be the first to say that string alignments take a while, especially the first few times that you do them. I have about 5 total hours into aligning and corner balancing my new-to-me E30 race car. The alignment was pretty far off, and that time includes measuring caster, setting up my scale pads and levelers, doing an initial alignment, corner balancing the car, and then re-checking and finalizing the alignment. Oh, and I don't have a lift.

Considering the amount of work involved, 5 hours isn't all that bad considering how long it would take me to bring it to a shop, and that I could fit it in to my free time at home.

The initial investment can be a deterrent, as well. While you can do it quite inexpensively, I opted to buy a complete string kit, a digital camber/caster gauge, and precise measuring implements. That is all in addition to my digital corner balance scales and roll off leveling pads. Even the price of the B-G Racing string kit alone is the cost of 2-4 professional alignments.

Lastly, what if you don't know what you're doing? There are a lot of great, thorough guides on the internet, but they are only going to get you so far. The real knowledge is when you begin to understand the what and the why behind making changes to your alignment to improve the handling of your car on track.

Truly, doing this yourself is not for everyone.

But you're not everyone, simply by virtue of the small, niche readership that is interested in the oddball and somewhat varied topics that I write about.

So, thus concludes our short introduction to string alignments. We will continue to explore this topic in greater depth over the coming months.